Not known Facts About Glazed Window Panels

Table of ContentsGlazing Panel Things To Know Before You BuyThe Best Strategy To Use For Glazed Glass PanelsAn Unbiased View of Double Pane Glass Panels For SaleThe Main Principles Of Fire Rated Glass Panels The Greatest Guide To Large Glazing Panels

These systems regularly include gaskets that are positioned between the stress bar and also mullions and also feature as thermal breaks and also assist with acoustic isolation. These systems require unique treatment in style as well as building and construction to ensure continuity of the gaskets at straight and also vertical transitions - fire rated glass panels. Gaskets are additionally utilized to cushion the glass on the exterior and interior faces of the glass.There is normally a space in the gasket at the corners after shrinkage occurs. With a properly created system the water that gets in the system at the gasket edges will weep out with the snap cover weep holes. To minimize contraction of gaskets back from the corners the usage of vulcanized corners and diagonally reduced splices are advised.

At the curtain wall surface border, maintaining continuity of the air barrier lowers airflows around the drape wall. Integration of perimeter flashings helps guarantee water tight performance of the drape wall and also its link to surrounding wall aspects. Proper placement of insulation at the drape wall border reduces power loss and also possible condensation concerns.

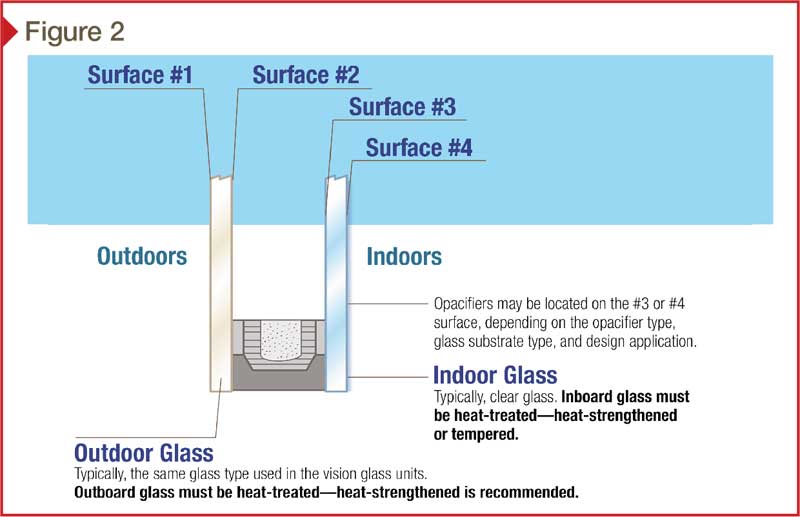

The spandrel location is usually not warmed, thus the interior atmosphere does not warm the mullions and also balance out the migration of the chilly temperature levels deep right into the wall surface (large double glazed glass panels). In the vision area the interior warmth aids to minimize the chilly as well as stops condensation. For this factor, do not protect in between the indoor section of mullions and surrounding wall building either.

Not known Details About Fire Rated Glass Panels

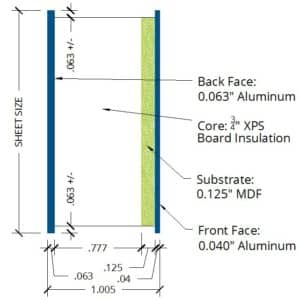

Back frying pans supply a 2nd line of protection versus water infiltration for locations of the curtain wall surface that are not visible from the inside as well as are hard to access. Water infiltration in nontransparent areas can continue for extended time periods triggering considerable damage prior to being identified. Back frying pans likewise are to be favored over foil vapor retarders in high efficiency as well as humidified structures as convection currents short-circuiting the insulation can cause condensation, moistening and also inevitably failure of these spandrel locations.

The steel sheet need to go to least two inches behind the glass as well as might be repainted or created to develop a texture, but reflective surfaces include the most aesthetic depth to the wall. Insulation must likewise be installed behind the darkness box if interior coatings stop space air from calling this location.

Keep in mind that this movement slightly misshapes the supports at the upright mullions. Specific devices of glass need to accommodate the motion of the bordering light weight aluminum frame by sliding along polishing gaskets, distorting the gaskets or a combination of both. The activity of the glass within the frame and also the movement forced in the anchors have a tendency to cause additional stress and anxieties right into a stick framed system.

Getting My Glazed Window Panels To Work

Laboratory-tested fire rated settings up might be required in unsprinklered structures by some codes as Perimeter Fire Containment Systems when the flooring settings up are called for to be fire-resistance rated. The scores of the Perimeter Fire Containment System should be equivalent to or more than the floor rating. These systems supply self-confidence that the products used for boundary control stay in place for the defined duration of the needed rating in a fire occasion.

Drape wall surfaces and also perimeter sealants call for maintenance to optimize the solution life of the drape walls. Boundary sealers, effectively created and installed, have a typical life span of 10 to 15 years although breaches are likely from the first day. Elimination and substitute of border sealers calls for meticulous surface area preparation as well as correct describing.

The very best technique for sustainability of curtain walls is to employ excellent layout techniques to ensure the sturdiness (optimum life span) of the installation and also to utilize systems that have a good thermal break and also high R-value (worths as high as R-7 are feasible with triple-glazed systems). Likewise, the use of low-e and spectrally careful glass coverings can dramatically lower energy loads and enhance comfort close to the wall surface.

Curtain wall design need to begin with the presumption that exterior glazing seals, boundary sealer joints as well as drape wall sills will certainly leakage. The complying with summarizes advised features: Select frames with wept glazing and pocket sills sloped to the outside to accumulate water that penetrates the glazing and also drain it to the outside.

Not known Factual Statements About Glazed Glass Panels

Curtain wall need to have a key air/water seal in between the shoulder of the tube at the airplane of the glazing pocket as well as the air obstacle of the surrounding building and construction. Boundary sealants work as a rainscreen for restricting air and also water infiltration through the outermost aircraft of the wall surface, but should not be counted upon as the single air/water infiltration barrier.

Glazing Approaches and Their Influence On Efficiency Stress Plate Glazing: In this system the glass as well as infill panels are mounted from the exterior, normally versus dry gaskets - insulated glazing panels. The external layer of gaskets is installed and the gaskets are pressed against the glass by the torque put on fasteners safeguarding a continual pressure plate.

The frame is repaired and exterior dry gaskets are mounted. visit their website Usually only the top interior mullion has a removable stop. The glass system is slid into a deep polishing pocket on one jamb far enough to allow clearing the opposite jamb and is after that moved back into the contrary glazing pocket and after that went down into the sill glazing pocket.

What Does Double Pane Glass Panels For Sale Do?

Occasionally this approach is called "jiggle" or "wiggle" glazing due to the control essential to obtain the glass right into place. Performance is slightly decreased since completely dry metal to steel joints take place at the ends of the removable quit at a point that should correctly be air as well as watertight. Damp sealer heel grains will certainly boost efficiency and also some systems include an additional gasket to develop an air barrier seal.

Architectural Silicone Glazing: In this system the glass or infill system is followed the frame with a grain of silicone. External silicone weather seals supplement the structural seal. Unitized systems are regularly structural silicone glazed, specifically if four-side SSG is wanted. Two-sided SSG, with stress plate glazing or shake glazing on the various other 2 sides serves to be field set up.

The CRF does not offer info regarding cold spots that might cause regional condensation. Tasks for which condensation control is navigate to this website an essential problem, Clicking Here such as high interior moisture structures, require project-specific finite component analysis thermal modeling making use of software application such as THERM. Cautious evaluation and modeling of interior problems is called for to accurately approximate the interior temperature of the air at the within surfaces of the glass as well as framework.